Case Study: Transforming Longwood Gardens with Advanced Mechanical & Plumbing Systems

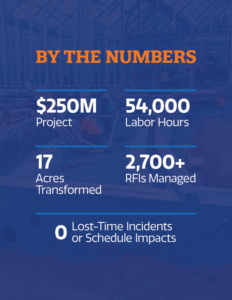

Longwood Gardens, one of the most iconic botanical gardens in the United States, embarked on its most ambitious project to date: a $250 million transformation of 17 acres into a world-class destination. This initiative required architectural beauty and cutting-edge mechanical, plumbing, and site utility systems to support sustainability and enhance visitor experience.

APEX Mechanical & Fabrication (APEX) was selected as a key partner in delivering these complex systems. With decades of expertise in fabrication, installation, and project management, APEX played a central role in ensuring the success of the Longwood reimagined project.

Download the full Longwood Gardens Case Study for an inside look at the systems, challenges, and solutions—complete with photos and testimonials.

Project Overview

The Longwood Gardens expansion encompassed brownfield and greenfield construction, meaning a mix of working with what’s already there and starting fresh on new ground. Seven distinct areas were designed, integrating breathtaking gardens, innovative water features, and advanced mechanical systems. APEX was responsible for the following mechanical services:

- Water Feature Systems: Infrastructure that powers fountains, pools, and decorative displays, controlling water flow, filtration, and recirculation.

- Irrigation & Stormwater Systems: Automated systems that deliver water to plants, gardens, and landscapes while also redirecting rainwater to prevent flooding and erosion.

- Domestic Water Systems: The clean water supply for drinking, restrooms, kitchens, and other everyday needs.

- Sanitary Waste Systems: The plumbing that removes wastewater safely to treatment or disposal systems.

- Grease Waste Systems: Specialized kitchen plumbing that collects fats, oils, and grease to prevent clogs and protect the sewer system.

- Natural Gas Lines: Piping that delivers gas for heating, cooking, and powering equipment.

- Compressed Air Systems: A utility that provides pressurized air to power tools, equipment, or controls in mechanical systems.

- pH Neutralization Systems: A system that balances the acidity or alkalinity of wastewater before it’s safely discharged.

- Fertilization Dosing Systems: Automated equipment that mixes and delivers the right amount of nutrients to plants through irrigation lines, improving growth and efficiency.

This broad scope required mastery across multiple piping and fabrication disciplines, from welding and brazing to High-Density Polyethylene (HDPE) pipe fusion and custom architectural metalwork.

The Challenge

Executing such a massive project while keeping Longwood Gardens open to the public created unique obstacles. Crews had to protect the Gardens’ iconic architecture and landscapes throughout construction. Work had to remain nearly invisible to guests and staff, preserving the site’s heritage and the visitor experience.

The scale of the effort demanded extraordinary teamwork. APEX collaborated with seven engineering firms, more than 30 construction managers, 70+ contractors, and 13 subcontractors—each with distinct roles and responsibilities. Aligning these moving parts required constant communication and discipline to keep the schedule intact.

Logistics added another layer of complexity. Specialized components were sourced from suppliers across Australia, Canada, and multiple European countries. Coordinating international shipping, navigating customs, and managing long lead times called for meticulous planning. Meanwhile, the design itself was a moving target: more than 1,250 drawings, 2,700 RFIs, and $2 million in change orders required flexibility and relentless attention to detail to prevent delays.

As if that weren’t enough, the COVID-19 pandemic brought material shortages, price volatility, labor constraints, and global restrictions into the mix. On the ground, crews also faced physical challenges. Installing intricate mechanical systems beneath the towering new West Conservatory demanded absolute precision, maneuvering large equipment and piping in tight, congested spaces with little room for error.

How APEX Delivered

We applied decades of expertise and a collaborative approach to deliver this multifaceted project with precision and efficiency. A core team, including the Project Manager, Project Engineer, General Foreman, and Safety Manager, led planning, coordination, and execution from start to finish.

- Planning & Preparation: From the start, we defined long-term goals, risk strategies, and construction packages that streamlined field use. Weekly updates ensured the latest revisions were always accessible.

- Safety Commitment: More than 54,000 labor hours were completed with zero lost-time incidents, a testament to APEX’s rigorous safety training and project-specific manuals.

- Innovative Design Tools: A full suite of 3D modeling, isometric drawings, and schematic development enabled clash detection and proactive sequencing, reducing costly delays.

- Coordination & Communication: Weekly multi-trade meetings and consistent project team check-ins ensured seamless collaboration.

- Responsiveness & Flexibility: Despite more than 2,700 RFIs and hundreds of revisions, APEX’s proactive oversight prevented any schedule impacts.

Results & Recognition

After more than three years of dedicated effort, Longwood Gardens gained a fully integrated, sustainable, and aesthetically seamless infrastructure:

- On-time completion of all scopes with no schedule delays caused by APEX

- Fully functional stormwater recycling and irrigation systems for sustainable operations

- High-end commercial kitchen systems supporting a new 5-star restaurant

- Innovative water features and treatment systems enhancing Longwood’s iconic displays

- Recognized with an ABC Delaware Excellence in Construction Award

Why This Case Study Matters

This project exemplifies how advanced mechanical contracting, site utility integration, and custom fabrication can transform infrastructure and visitor experiences. For facility owners, architects, and contractors, the Longwood Gardens project highlights:

- The importance of early-stage planning and risk mitigation

- The role of technology-driven design tools in preventing conflicts

- How collaboration across diverse stakeholders ensures success

- The impact of sustainable water and utility systems on long-term operations

The Longwood Gardens case study demonstrates APEX’s ability to deliver on the most complex, high-stakes projects while prioritizing safety, sustainability, and schedule integrity. The result is a lasting model of excellence in mechanical and plumbing system integration.

Download the full Longwood Gardens Case Study for an inside look at the systems, challenges, and solutions—complete with photos and testimonials.